Official World Radio Controlled Crawler Association Rules 2023

Introduction

This rulebook defines the World Radio Controlled Crawler Association events that are hosted throughout the world. Vehicles, scoring, and classes are included to give event coordinators and attendees common rules.

Description of Events

The objective of an event is to provide an enjoyable gathering for Radio Controlled Crawler enthusiasts. Events can range from social to competitive in nature, and include a wide range of vehicle and challenge types.

Addendum (SWC’s note)

Additions that are not in the rules, but are written in the forum (https://wrcca.net/forums/forum/wrcca/wrcca-rules/1049-wrcca-official-comp-rules-2023#post1049) by World Radio Controlled Crawler Association (WRCCA):

WRCCA Statement of competition classes

Due to the amount of competition classes in WRCCA we have stated a guideline that minimum of three (3) competition classes including Pro class has to be competed in single Worlds/Continental Championship competition of WRCCA Rock Crawling. The other 2 or more classes can be chosen by the factors such as popularity of the classes in certain region/country. Pro class is the very spine of WRCCA rules and competitive crawling and it has to be included in these events.

We are also following closely the driver numbers of of each class globally and can take action wether any of the classes are significally dropping numbers and competitions in the future. For us in WRCCA it is the main goal to keep things simple with an attempt to grow while keeping the excistent drivers interested.

SECTION 1: Professional Scoring Penalties

1.1 – Points:

Reverse: 1 point

Gate Marker: 10 points

Rollover: 5 points

Boundary Marker: 10 points

Vehicle Touch (Repair & Repositions): 10 points

Course Direction: 10 points

1.2 – Back Up/ Reverse: (1 pt) Point is given when a vehicle reverses course after making forward progress. Reversing is defined as any of the tires moving in the reverse direction, whether engaged or in freewheel and/or whether intentional or not. Once a reverse penalty is given, no further reverse penalty can be given until the vehicle makes forward progress. No penalty is given if the backward movement occurs while the vehicle is in the rollover position. (See Sec. 6 Rollover Position) If a driver begins a course in reverse, a reverse penalty will occur immediately. (See Reverse examples and explanations Sec. 7)

1.3 – Rollover: (5 pts) Points are given when vehicles rollover, and cannot be corrected without touching. Once the vehicle has stopped it may be rolled over and the 5-point penalty shall be given. Vehicles that land back on their wheels are not penalized. No reverse penalties are given until the vehicle is up righted and back on all 4 tires. Drivers must execute a legal roll over recovery, or they will be given a reposition penalty. (See Sec. 6 Legal Rollover)

1.4 – Vehicle Reposition Touch: (10 pts) All vehicle touches excluding “Rollovers” (See Rollover rule, Sec 1) are given an automatic 10 points. The judge will stop time when the driver requests a vehicle touch or the judge calls a touch penalty. The vehicle is then moved by the driver to the previously cleared gate with the rear axle aligned to that gate. If the vehicle cannot be aligned to the gate due to course design, the judge will reposition the vehicle to the next stable location after the cleared gate. This location will be used for all drivers. Note: All gates for progress are still “live” unless a gate has already been deemed “dead”.

– 1.4.1 – Vehicle Touches: Include but are not limited to: repairs, repositions, and intentional touching of the rig by the driver. Touch penalty will occur if the driver interacts with intent to cause advantage or control a falling vehicle.

* Special considerations: Driver safety is most important and touch penalties should not accumulate from accidental interaction. When vehicle and driver make accidental contact, the judge or driver(s) assisting scoring shall stop time and determine if standard reposition should occur to prevent advantage, or if driver can continue without further interaction.

* Example 1: Vehicle falls and hits driver, coming to rest on the driver’s foot. Judges stop time, and call for a no-penalty reposition, as the driver could gain course advantage by continuing to drive over the foot. If the driver ignores reposition and drives over foot, it becomes an event rule violation of course modification and the driver is disqualified.

* Example 2: Driver stumbles and steps on vehicle. Judges stop time to ensure the driver has stable footing, and to assess vehicle position. No advantage is seen, so time starts and the driver resumes without reposition.

* Example 3: Vehicle falls and hits driver, coming to rest further downhill. Judges stop time and assess that no advantage was made from the fall, so time restarts and driver resumes.

– 1.4.2 – On Course Repairs: Must be completed on course and in the spot of which the driver decided to take the repair. Repairs must be made within the course time, while the course timer will continue to run. Once repairs are completed, the timer is stopped and the vehicle is repositioned to the previous gate cleared. If repairs cannot be made within the course time, the driver is given a DNF minus progress points for that course. There are no restrictions on whom or how the repairs are made.

– 1.4.3 – Off course repairs (Optional): A driver can call time to make an off-course repair at events where deemed acceptable. Repairs should be completed within 30 minutes, or the driver is given a DNF minus progress points. If the repair is made in the allotted time the driver must return to the last previous gate cleared. A 1 minute time penalty will be subtracted from the time that is left on that course, the timer will continue once the vehicle makes forward progress.

– 1.4.4 – Vehicle Out of Spec: If the Judge has reason to believe a vehicle is out of spec during a course run, he may call time to stop. At that point, no additional inputs may be given by the driver to the vehicle via touch or radio control. The Judge must mark the vehicle’s location and perform a tech inspection in the specified tech area (same manner as all other tech inspections). If the vehicle has been deemed within spec, the driver and vehicle will return to the location marked by the judge and the clock will start once again. If the vehicle is now out of spec and the Judge has determined that the vehicle has gained an advantage, the driver must take a repair (see rule 1.4.2 or 1.4.3 event organizers discretion) to correct the problem. If the problem cannot be corrected to bring the vehicle back within spec, the driver will receive a DNF for that course (see rule 1.8 ). If a vehicle falls out of spec due to breakage on course and the Judge determines the driver has not gained an advantage, then the driver may be allowed to continue on course without stopping time and requiring a tech inspection. Bodies are not included in this exception, and must be replaced immediately, standard repair procedures and penalties apply.

1.5 – Gate Marker (10 pts each): Each gate will be composed of 2 gate markers. Points are given when 4 wheels do not travel between gate markers or any part of the vehicle touches a gate marker. A gate marker will remain ”live” for the entire duration of the attempt on the course. Gate markers that are moved by anything other than the vehicle’s actions will be replaced immediately before the driver is allowed to continue. Once any gate marker has been touched by the vehicle, no more penalties will be given for that gate marker. Only when a gate penalty is assessed will that gate marker be deemed ”dead”. No further penalties will be assessed at this point for that gate marker. (See Gate Marker and Gate Clearing explanations, Sec. 7.)

1.6 – Boundary Marker (10 pts each): Points are given when any part of the vehicle touches a boundary marker. Once a boundary marker is touched the judge then will stop time, and the vehicle is then moved back by the driver to the previously cleared gate with the rear axle aligned to that gate. If the vehicle cannot be aligned to the gate due to course design, the judge will reposition the vehicle to the next stable location after the cleared gate. This location will be used for all drivers. A boundary marker will remain live (and will be replaced immediately if moved.) for the entire duration of the attempt on the course, and if they are moved out of position they will be replaced immediately before the driver is allowed to continue. Boundary markers are not required in the design of a course.

1.7 – Maximum Penalty Points:

– 1.7.1 – The maximum points per course is 40 (Optional). At that time, the driver is given a DNF and the run is complete and the vehicle should be removed from the course.

– 1.7.2 – The maximum points per gate is 20. (Optional) Once a driver has reached the maximum of 20- penalty points for that gate they will be placed with the rear axle aligned to that gate’s exit. If the vehicle cannot be aligned to the gate due to course design, the judge will reposition the vehicle to the next stable location after the cleared gate. No progress points are given for the gates not cleared.

1.8 – DNF (Did Not Finish) (40 pts): Are given anytime a driver cannot complete a course for any reason. (Time expired, Point-Out, Vehicle not Repairable, etc) Progress points are awarded for each gate completed.

1.9 – DNS (Did Not Start) (50 pts): Are given anytime a driver cannot start a course for any reason. Vehicle must start the course under its own power.

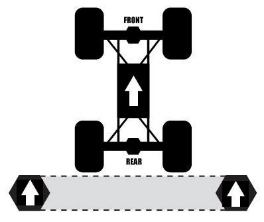

1.10 – Gate Progression (-2 progress point): Shall be awarded to drivers for each gate after it has been cleared during the attempt of a course. All gate penalties are assessed and given before a progress bonus is awarded. Progress is awarded when during the same attempt and in the intended course direction at least one front and one rear tire passes completely through the gate. To receive the progress bonus without a gate penalty, all four tires must pass completely through the gate during the same attempt and in the intended course direction (See Illustration A). Progress points are deducted from the total course score. Once a driver has pointed out, no further Progress points will be awarded. (See 1.5 for examples of Gate Penalties.)

Illustration A

1.11 – Timer Pause: A driver may call for time to stop so that he or she may safely reposition themselves on the course. This time shall be used for the purpose of driver safety and may not be used to survey the course or for any other advantage, the judge has the right to restart time at any point. Most typically, the timer will resume when the competitor resumes driving or touches his or her car (for a roll over). A judge may also call a stop of time to reposition themselves to make a more accurate call on a penalty, drivers may also request a stop of time for this same reason. Example: “Stop time., Hey Judge I’m going to approach this gate from this direction and want to make sure you have a good view of my car, do you want to reposition?”

1.12 – Course Direction (10 pts): Gates must be cleared in their intended direction and sequence. If the vehicle progresses an un-cleared gate in the wrong direction, or out of sequence will result in a 10-point penalty and the judge will stop time. (Progress is at least one front and one rear tire needs to be completely through the gate). The vehicle is then moved back by the driver to the previously cleared gate with the rear axle aligned to that gate. If the vehicle cannot be aligned to the gate due to course design, the judge will reposition the vehicle to the next stable location after the cleared gate. This location will be used for all drivers. Once progress is awarded for a specific gate, it can be passed through in any sequence or direction.

SECTION 2: Vehicle Requirements

2.1 – General: (Excluding Performance Scale Class which is written on section 2.6 forwards)

– 2.1.1 – Vehicles are limited to 4-wheeled vehicles only, unless special exemption is given to the class. These 4 wheels can be the only source of propulsion for the vehicle.

– 2.1.2 – All vehicle specifications regardless of class, body or bodiless the measurements are to be taken in the vehicle’s ready to run condition while sitting on a flat surface (i.e. tech table).

– 2.1.3 – Wheelbase is measuring from centreline of front axle stub to centreline of rear axle stub.(See Section 6 Wheelbase)

– 2.1.4 – The vehicle’s roof must be raised a minimum of 1”/25.4mm. from the main chassis to resemble a cockpit. The frame sides must be an overall minimum of 1”/25.4mm tall (The cockpit & frame side are to be measured vertically from where the hood intersects the cab).

– 2.1.5 -Vehicles should resemble a 1:1 vehicle.

– 2.1.6 -Shocks and fasteners (nuts, bolts, washers, or spacers) shall not be included in the measurements of the vehicle.

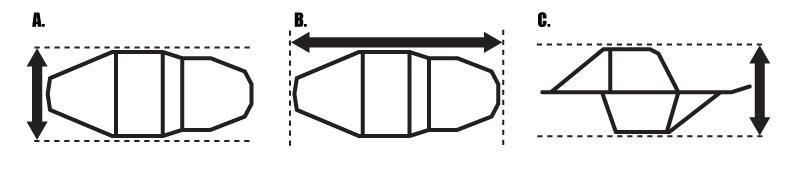

– 2.1.7 – Vehicles body/ bodiless measurementsmust reach a minimum of (A) width, (B) length, and (C) height. Measurements may include, but not limited to bumpers, stingers, frame-rails, side-rails, skid plates, roof, hood, and side panels. See Illustration B.

Illustration B

– 2.1.8 – Winching down of the axles is allowed. The winch line must be attached within a 1/2″/12.7mm of the centre of the axle, and by a single attachment point only.

– 2.1.9 – There are no limitations on the amount of radio channels used on a vehicle. Unless specified in the class rules.

Measurement methods – Vehicle track width is determined by measuring the bottom of the outermost edge of the front and rear tires while the vehicle is sitting on level ground. Vehicle wheelbase is determined by the distance between the axle shafts in a resting position , at no point during articulation of the suspension must the wheelbase exceed the specific class’s maximum amount.

Classes

2.2 – Super Class:

– 2.2.1 – Vehicle wheelbase is limited to a minimum of 16”/406.4mm and a maximum of 18”/457.2mm.

– 2.2.2 – No limits to steering configuration.

– 2.2.3 – Wheel/ rimis limited to a minimum 3.2”/81.28mm or larger at the bead surface. Wheels may be modified provided that the tire bead surface is not less than 3.2”/81.28mm in diameter.

– 2.2.4 – Tires may be modified from other size tires using only pliable rubber.

– 2.2.5 – Vehicle body/ bodiless measurements must be greater than or equal to 12″/304.8mm overall length, 3″/76.2mm overall width and 3″/76.2mm overall height.

2.3 – Pro Class:

– 2.3.1 – Vehicle wheelbase is limited to a maximum of 12.5”/317.5mm.

– 2.3.2 – Vehicle track width is limited to a maximum of 12.5”/317.5mm.

– 2.3.3 – Wheel/ rim is limited to 2.2”/55.88mm or smaller at the bead surface. Wheels may be modified provided that the tire bead surface does not exceed 2.2”/55.88mm in diameter. With a tire mounted no exterior component of the wheel including but not limited to the bead lock ring shall exceed 2.55″/64.77mm.

– 2.3.4 – Tires may be modified from other size tires using only pliable rubber but must not exceed a total uncompressed outer diameter of 6”/152.4mm.

– 2.3.5 – Vehicles are limited to 2-wheel steering only.

– 2.3.6 – Vehicle body/ bodiless measurements must be greater than or equal to 8″/203.2mm overall length, 3″/76.2mm overall width and 3″/76.2mm overall height.

– 2.3.7 – Limited to two motors.

2.4 – Mini Class:

– 2.4.1 – Vehicle wheelbase is limited to a maximum of 9”/228.6mm.

– 2.4.2 – Vehicle track width is limited to a maximum of 9”/228.6mm.

– 2.4.3 – Wheel/ rim is limited to 1.9”/48.26mm or smaller at the bead surface. Wheels may be modified provided that the tire bead surface does not exceed 1.9”/48.26mm in diameter. With a tire mounted no exterior component of the wheel including but not limited to the bead lock ring shall exceed 2.2”/55.88mm

– 2.4.4 – Tires may be modified from other size tires using only pliable rubber but must not exceed a total uncompressed outer diameter of 4.95”/125.73mm.

– 2.4.5 – Vehicles are limited to 2-wheel steering on the front axle only.

– 2.4.6 – Vehicles are limited to the use of 2 channels radio control (one for steering & one for throttle) only. Neither channel can be used to perform more than one function. Radio systems with more than 2 channels are allowed but only 2 channels can be used to control the vehicle.

– 2.4.7 – Vehicles are limited to 1 ESC & 1 servo only.

– 2.4.8 – Vehicles are limited to 1 motor powering both of the axles.

– 2.4.9 – No driver controlled devices, other than steering and throttle control, will be allowed. Independent throttle control to the front or rear axles (“burn” or “dig”),(winching down the axles, and forced articulation are not allowed in this class.)

– 2.4.10 – Vehicle body/ bodiless measurements must be greater than or equal to 6.75″/171.54mm overall length, 2.5″/63.5mm overall width and 2.75″/69.85mm overall height.

– 2.4.11 – Motor must be chassis mounted. Motor mount cannot be part of or directly coupled to an axle.

2.5 – Sportsman Class:

– 2.5.1 – Vehicle wheelbase is limited to a maximum of 12.5”/317.5mm.

– 2.5.2 – Vehicle track width is limited to a maximum of 12.5”/317.5mm.

– 2.5.3 – Wheel/ rim is limited to 2.2”/55.88mm or smaller at the bead surface. Wheels may be modified, provided that the tire bead surface does not exceed 2.2”/55.88mm in diameter. With a tire mounted, no exterior component of the wheel, including but not limited to, the bead lock ring shall exceed 2.55″/64.77mm.

– 2.5.4 -Tires may be modified from other size tires using only pliable rubber, but must not exceed a total uncompressed outer diameter of 6”/152.4mm.

– 2.5.5 – Vehicles are limited to 2-wheel steering only.

– 2.5.6 – Bodied Vehicles only, typically a lexan body that is removable from chassis. Bodiless vehicles are prohibited. Bodies must be of original width and resemble a 1:1 vehicle with cab, door, and hood panels. Vehicle “body” measurements must be greater than or equal to 8″/203.2mm overall length, 3″/76.2mm overall width and 3″/76.2mm overall height.

– 2.5.7 – Vehicles are limited to the use of 2 radio channels (one for steering & one for throttle) only. Neither channel can be used to perform more than one function. Radio systems with more than 2 channels are allowed, but only 2 channels may be used to control the vehicle.

– 2.5.7 – Vehicles are limited to 1 ESC, 1 Motor & 1 servo only.

– 2.5.8 – Motor must be chassis mounted. Motor mount cannot be part of or directly coupled to an axle.

2.6 – Performance Scale Class:

**** Local event organisers are free to modify these rules to suit your local events, however, all state, regional, national and world championship events should follow the official rule set****

General specs

– 2.6.1 – Vehicles should represent a vehicle that has been modified to become a capable trail rated/competition based rig and is not necessarily street legal.

– 2.6.1.2 – Vehicles must run a minimum full body from the grill to the B-pillar. The grill can not be cut or modified. (Bodies without a grill must have full hood/bonnet). Wheel arches and headlights may be trimmed for clearance.

– 2.6.1.3 – Cab only configured rear chassis must have frame or bar work or tray (bare chassis and shock hops is not acceptable). Removal of the roof is allowed so long as roll gage/half interior is fitted.

– 2.6.1.4 – The body (Including tray, cage or any other bar work) must be (3″/76.42mm) longer than the wheelbase.

– 2.6.1.5 – Body / Cage work must be at least 4.5″/114mm minimum height.

– 2.6.1.6 – Minimum body width is 5”/127mm for the full length of the passenger cabin. (Passenger cabin is defined as from the furthest forward point of the front windscreen and the furthest rearward point of the rear window)

– 2.6.1.7 – Sectioning or narrowing of the body is allowed from the A-Pillar forward and the B-Pillar backward. But the body must still follow reference 2.6.1.2, 2.6.1.4 and 2.6.1.6.

– 2.6.1.8 – The inner side wall/ shoulder of front tyres, measured at the axle centre must be covered by bodywork when viewed from above at rest. Flares can be added to the body to obtain coverage.

– 2.6.1.9 – A front bumper is required. It must be a minimum of 2.75”/70mm wide centered to the front chassis rails and must flow through a continuous line (see pictures below). Chassis mounted bumpers need to project forward at least 3mm past the body. Body moulded front bumpers qualify and must not deflect inwards.

– 2.6.1.10 – Clear bodies, “swiss cheese” bodies are not permitted. Consider realism.

– 2.6.1.11 – No electrics other than steering servo are permitted to be mounted or fixed to axles or suspension links.

– 2.6.1.12 – Receivers are limited to 2 used channels only.

Tires and wheels

– 2.6.2 – Vehicles are limited to 2.2”/55.88mm wheels/rims or smaller at the bead surface.

– 2.6.2.2 – Tires are limited to 4.8”/122mm maximum external diameter and a maximum width of 55mm from side wall to side wall. Tire size will be determined by advertised manufacturer specs. (Tires without available specs will be measured off the truck as mounted on the wheel laid flat).

– 2.6.2.3 – Siping, grooving, shaving and removal of the lugs from any kind of production tire is allowed as long as they meet rule 2.6.2.2 Only production tires are allowed that meet 2.6.2.2 rules. Internal tire modifications permitted are trimming and sanding of tires.

– 2.6.2.4 – Original size of the tire must be maintained. Cut and shut, narrowing, reducing or increasing, of any kind, is not allowed. Tire carcass cannot be cut.

– 2.6.2.5 – Production pin tires, even if they meet rule 2.6.2.2, are not allowed.

– 2.6.2.6 – Weighted knuckles/ knuckle weights must fit within the bead circumference (Suspended knuckle weights similar in design to “rock magnets” are not permitted)

– 2.6.2.7 – Carbon fibre wheels/rims must have offset or beadlock ring built into their design (Flat face glue on wheels/rims not permitted). Internal rings are required and foams must not be visible from any angle.

Drive train

– 2.6.3 – Vehicles are limited to front wheel steering only.

– 2.6.3.2 – Vehicles must be shaft driven only and powered by a single motor. No ”Motor On Axle” (MOA) of any kind. Your axles must be driven by one transmission or transfer case and a minimum of two drive shafts . No separate throttle control of drive shafts or axles.

– 2.6.3.3 – No front or rear dig or axle disconnects are allowed.

Chassis

– 2.6.4 – Chassis can be any configuration of C-Channel, tub, tube, rod, moulded plastic, or plate. Shock hoops must be no higher than 2.75”/70mm above the lowest point of the skid.

(NOTE: This is defined as the point in which the shock “hoop” meets the chassis rail.)

– 2.6.4.1 – Upper link mounts on the chassis to be no greater than 1.18”/30mm higher than the lowest point of the skid.

– 2.6.4.2 – Chassis must extend covering all axle centrelines. Two piece sectional chassis are permitted, provided they are screwed, bolted or welded/brazed together to form a single chassis rail. Chassis length is to be constructed using a maximum of two pieces overlapping/joined for the full length of the skid. The front most point of the skid must not be further forward than 1/3rd of the total wheelbase.

– 2.6.4.3 – Vehicle wheelbase is to fit the dimensions of the body used. In the instance a tray-back/truggy cage is fitted, the wheelbase will be approximately defined as between double the distance of the front axle to the A-pillar and double the distance of the front axle to the B-pillar.

– 2.6.4.4 – Battery trays must be mounted to the chassis.

– 2.6.4.5 – The section of the chassis that counts as the one continuous length must also have the skid plate attached to it directly.

SECTION 3: General Event Rules & Event Management

3.1 – WRCCA recognizes that some clubs may need to amend the WRCCA Rules to accommodate their terrain and group size at a local level. These rules changes shall be posted in event notifications, and clearly communicated to all competitors prior to competition. Multi-Club events that are Non-WRCCA Events are encouraged to run as strict WRCCA Rules as possible. All WRCCA Sanctioned Events are required to strictly follow WRCCA Rules. Any rules exception for sanctioned events must be pre-approved by the WRCCA. All major events shall have a minimum of three (3) Marshalls. These Marshals shall be announced at the drivers meeting before any courses are run. Marshals need to be in attendance for the duration of the event. Any rule changes necessary due to conditions specific to an event must be decided and voted upon by Event Marshals. Any questions on discrepancy of the rules or scoring shall only be handled and voted on by Event Marshals. All courses shall be inspected by all of the Event Marshals with the course designer prior to the start of the event. Courses may open after the Event Marshals have given approval.

– 3.1.1 – Any event in which a National Invite is awarded is deemed a Sanctioned Event. This includes major events, state championships, state crawl-offs, etc.

3.2 – Scores are ranked by the cumulative total of all course scores. Lowest total score wins.

– 3.2.1 – Finals course scores are added to total event scores. DNS (50 pts) is given to drivers that did not compete in the finals

3.3 – Tie Scores:

– 3.3.1 – Driver with the greater amount of perfect maximum negative point scores wins. If these are even, the count continues to next best negative scores and amount of them. And so on. If all courses are tied, drivers can proceed to one course shootout to define the winner of the competition.

– 3.3.2 – Optional: In the event of a tie score the competitor with the lowest time on all courses will be chosen the winner over the other competitor(s) with the same score.

3.4 – No Pre-running Courses: Drivers that pre-run a course will receive a DNS (50pt) for that course.

3.5 – Course Cut Off Time: Drivers must be in line to run a course before the set course closure time. Drivers who fail to do so will be scored a DNS (+50). Drivers may be permitted to run due to extraordinary circumstances at the head marshals discretion.

3.6 – Winching: (Other than that done to the suspension) or ramping of any kind is not allowed. Using any device (other than the tires) such as ramps or other objects to make progress in any direction is prohibited and will result in a DNF for that course.

3.7 – Multiple Class Vehicle: A vehicle may be run in more than one class at an event, So long as it meets class specs.

3.8 – Vehicle Exchange: Vehicles cannot be exchanged for another vehicle during the competition.

3.9 – Vehicle Sharing: Vehicle sharing is allowed. No more than two drivers can share the same vehicle. Drivers sharing a vehicle must notify event organizers during Tech Inspection or Check In. Event organizers or Marshals may make any changes to the running order of the drivers sharing a vehicle they deem necessary to avoid controversy.

3.10 – Changing Vehicle Specs (On Course): The vehicle must run a course entirely with the same wheelbase, track width, ride height, and tires it started that course with. Any changes to the vehicle (other than winching down the suspension or forced articulation) by the driver, another person, or any device, while on the course are prohibited. If any kind of modification is done to the vehicle on the course it will be defined as DNF (40pts) minus possible progresses that are achieved till that point.

3.11 – Changing Vehicle Specs (Off Course): Drivers may make changes to wheelbase, track width, ride height, and tires between course runs, as long as the vehicle remains within the specs for its class.

3.12 – Course Modification: No modification to the course is allowed by anyone. This includes, but not limited to, removing of rocks, stacking of rocks, purging a puddle of water, blowing/wiping dirt from rocks, removing vegetation, using objects (including driver’s body), or other types of modifications to a course that could gain a driver an advantage. If any kind of modification is done by the driver or their crew score will be defined as DNS (50pts).

3.13 – Event Rule Violation: Any violations of event rules are subject to automatic disqualification by judges, event organizers, or WRCCA. If violation of rules is severe and/or recurring the WRCCA reserves the right to ban the violator from competition for up to one year.

SECTION 4: Course Design

4.1 – Gates Construction: Gates consist of at least 2 Gate Markers.which are numbered and indicate direction of progression.

4.2 – Gate Width (Minimum Width): Super Class = 20“/508mm, Pro & Sportsman Classes = 16”/406.4mm and Mini & Performance Scale Classes = 12”/304.8mm. Measurements are from inside to inside of each gate marker.

4.3 – Gate Quantity: Recommended10 Gates per course (not including bonus gates).

4.4 – Course Quantity: A minimum of 3 Courses per event is recommended.

4.5 – Gate Distinction: Courses in close proximity to each other should be distinguished by different colored gates or markings.

4.6 – Live Gates: Gate markers that are live and designed as part of the course that count for penalty must also have progress or bonus points awarded.

4.7 – Start Lines: Courses may consist of a start gate, chalk line or any other type of designated starting area. Start lines are only used to start the course clock.

– 4.7.1 – Scoring starts when time has started. Scoring stops when the course is finished.

4.8 – Course Completion: The course is finished once last progression gate is completed and progress has been awarded (see rule 1.10).

4.9 – Bonus (Optional): Bonusesare extra gates placed anywhere on the course by course designers for bonus credit.

– 4.9.1 – All penalties apply during the bonus attempt to the regular score even if the bonus is not completed or aborted.

– 4.9.2 – Course must be completed in order for the bonus to be awarded.

– 4.9.3 – Bonus may consist of more than one gate.

– 4.9.4 – Bonus Gates are run in the intended sequence and direction set by the course designer.

4.10 – Alternate (Optional): Alternate gates are secondary gates placed anywhere on the course by course designers for bonus credit.

– 4.10.1 – All penalties apply during the alternate attempt to the regular score even if the alternate is not completed or aborted.

– 4.10.2 – Course must be completed in order for alternate to be awarded.

– 4.10.3 – Alternate may consist of more than one gate.

– 4.10.4 – Alternate Gates are run in the intended sequence and direction set by the course designer.

SECTION 5: Judging

Judge Requirements:

Depending on the size of the event, organizers and/or clubs should plan staffing their courses according to the needs of the event. Local/Club events can use a wider variety of judging arrangements like small groups, or the next driver in line. WRCCA sanctioned events should have judging arrangements planned prior to their event (team format, volunteer/paid, or judging assignments/schedule). Any group or individual found to be cheating will be disqualified from the competition, and can be disqualified from all sanctioned events if deemed necessary by the WRCCA.

5.1 – Judge Responsibilities: Judges are responsible for watching vehicles while on the course, calling penalties, marking penalties, and keeping time. After the course is completed or time elapses the judge will calculate course score and indicate total on scoresheet and /or driver card.

– 5.1.1 – Judges should call out penalties when they occur.

– 5.1.2 – Judges are responsible for keeping spectators at a safe distance from the course to avoid spectator interference.

5.2 – Judges Per Course: Whenever possible this should be done by at least 2 people per driver. One Judge to call out penalties and one Judge/Scorekeeper, to record penalties, tally maximum penalties, keep time, etc.

5.3 – Spectator Interference: If a spectator accidentally interferes with the vehicle the driver should not be penalized. If a fan intentionally interferes with the vehicle, and significantly changes the outcome to the driver’s advantage then the driver should be penalized appropriately at the discretion of the judge. Intentional spectator interference includes but is not limited to if a fan stops a truck from falling in water, off a cliff, or other obvious hazard to avoid damage.

5.4 – Spotters (Optional): If spotters are permitted by event organizers drivers are responsible for identifying the driver’s spotter. Only designated spotters shall be allowed on course with the driver and judges. All penalties committed by the spotter shall count towards the driver’s total score. (i.e. touches, course modification, and etc.)

5.5 – Stopping after Attempt: Once a driver has finished their attempt at a course, the driver must remove their vehicle from the course as quickly as possible, to allow the next driver to attempt the course. If a driver fails to adhere to the rule and continues to drive on the course, the driver may be subjected to a 50 point DQ for that course.

SECTION 6: Glossary of Terms

Active Suspension: A suspension that is interlinked (such as the 1:1 Scorpion, excluding the air bags used to raise and lower the vehicle) which by design moves part of the suspension in one direction when moved from another. This does not have any driver input to be legal.

Body: Formed as a single piece of seamless rigid material, integrating Roof, Door (sides), and Hood sections.

Bodiless: Other construction techniques that include door (side), roof, and hood panels representative of 1:1 vehicles. Including but not limited to bolted, welded, brazed, and forming techniques.

Course: A course is the terrain that consists of a start gate, an end gate, and all the terrain in between them. Every course has an intended direction of travel, or “flow”, through the gates.

Event/Competition: The coming together of drivers at a certain place and time to compete on single or multiple courses.

Forced Articulation: Is the use of something such as hydraulics or electronics to literally force the suspension to move in a driver-controlled manner.

Gate: A gate is used to mark an obstacle within a course and/or guide the vehicle through the course. A gate consists of 2 gate markers measuring no less than; 20″/508mm for the Super class, 16”/406.4mm for Pro and Sportsman classes, and 12“/304.8mm in Mini and Performance Scale classes from inside edge of one marker to the inside edge of the opposite marker. The gate is the entire area between the gate markers; determined by the size of the gate markers and the distance between them. See Illustration C . Every gate has an intended direction of travel, or “flow”, through the gate. This direction will be marked, explained or implied by the course designers. All gate markers are “live” until touched .

Illustration C

Legal Rollover Recovery: The vehicle must be completely at rest and may not have any transmitter input during the Rollover Recovery. The rig must be smoothly rolled over (sideways not end over end) from driver or passenger sides by holding the truck by the chassis or body (Not tires, wheels or axles). The driver may only attempt to roll the vehicle in one direction. At no time during the Recovery can the vehicle slide in any direction or lose contact with the ground. Once the truck is rolled over it must be able to hold its position on its own long enough for the Judge to determine it is stable and remain within the course boundaries. The course may be continued at this point. If any of the above criteria is not met, a Reposition penalty (10 pts, see Vehicle Touch rule, Sec 1) will be given instead of a Roll Over (5 pts).

Rollover Position: A vehicle is considered to be in the Rollover Position when both wheels on the same side of the vehicle break a 90 degree vertical plane from horizontal level (NOT the crawling surface).

Vehicle track width: Is measured from the outermost edge of a tire to the outermost edge of a tire.

Wheelbase: Is measured from centre of axle nut to centre of axle nut. The vehicle should be set down on a flat surface by the driver. The front wheel on the side that is being checked, must be pointing straight forward. At that time, the driver will then cycle the suspension through it’s complete extension and compression range while the judge measures the vehicle’s maximum wheelbase. At any point the vehicle’s wheelbase cannot extend beyond the maximum limit of it’s class. All the above procedures must be duplicated on the opposite side. Note: All vehicles will be teched in the same ready to run condition, and set up as the vehicle will be run on the course. If the vehicle’s wheelbase is affected by radio control it must be cycled or activated during tech inspection.

SECTION 7: Penalty Examples and Additional Penalty Definitions

The examples and definitions used in this section are intended to help explain rules in previous sections, not override them.

7.1 – Back Up/ Reverse Examples:

– 7.1.1 – If the driver intentionally drives the vehicle in reverse, a reverse penalty will occur.

– 7.1.2 – If the vehicle stops on an incline and then rolls backwards a reverse penalty will occur.

– 7.1.3 – If a vehicle is climbing an obstacle and is bounced backward by the terrain but the tires are still moving forward, no reverse penalty will occur.

– 7.1.4 – If a vehicle flips over backward, without the driver reversing, no reverse penalty will occur.

– 7.1.5 – Once a reverse penalty has been assessed, no further reverse penalty can be assessed until the vehicle makes forward progress.

– 7.1.5.1 – Example: Reversing, stopping, and then reversing again will only result in one reverse penalty.

– 7.1.6 – Reverse penalties are assigned at the Judge’s discretion if the actions performed by the Vehicle/driver is not clearly defined by the rule.

7.2 – Clearing of a Gate Examples:

– 7.2.1 – A gate is considered progressed when at least one front and one rear wheel passes between the two gate markers, and all four tires are past the gate in the intended direction of the gate.

– 7.2.2 – One wheel from the front axle and one wheel from the rear axle passes between two gate markers to considered it progressed gate. This however will result in a Gate Marker penalty of +10 points and the -2 gate progression points are awarded.

– 7.2.3 – All gates must be cleared in the intended sequence of the course layout (gate 1, then gate 2, then gate 3 and so on).

– 7.2.4 – A vehicle may travel through a gate while it is in reverse and still clear that gate as long as it only travels though in the intended direction (reverse penalty(s) will be assessed as necessary).

– 7.2.5 – If all four wheels of a vehicle must pass between two gate markers that gate is considered a progressed gate with no penalties and a gate progress bonus is awarded.

– 7.2.6 – If one wheel only from the front axle or one wheel only from the rear axle passes between two gate markers that gate is not considered a progressed gate.

7.3 – Gate Marker Penalty Examples:

– 7.3.1 – At any time a gate marker is touched by a vehicle, a Gate Marker penalty is assessed.

– 7.3.2 – A driver can only continue with the course when a gate is cleared or 20 pts (if optional by pass rules are used) at that gate is accumulated.

Section 8: Sportsmanship

8.1 – Sportsmanship: Good sportsmanship is required at World RC Rock Crawling Competitions. If a competitor or team member (including but not limited to spotters) promotes unsportsmanlike conduct, they and/or their team members may be penalized upon the Marshal’s review of the incident. Unsportsmanlike conduct includes but is not limited to rude or abrasive actions towards officials or other teams or spectators, destroying property, displaying drunken or disrespectful behaviour, use of excessive on course profanity or kicking/throwing their controller or rig. The violator(s) and/or their team members may be penalized upon the Marshal’s review of the incident. Unsportsmanlike conduct may result in a 50 (DNS) for the course, and/or disqualified from the competition.

8.2 – No alcohol or drugs: Are not allowed on course during competition. Intoxicated competitors will be asked to leave the competition area, at the marshal’s discretion. If further action is required to remove an intoxicated person from the course, Disqualification or Ejection from the event may occur at the discretion of the head marshal or event organizers.

8.3 – Violation of Intent: The intent of a written rule may include areas not explicitly expressed or illustrated. *The WRCCA Rules Committee has the ability to define the intent of a rule. A violation of the intent of a rule may be considered a violation of the rule itself. Rulings on Violation of Intent shall only be made by the WRCCA Rules Committee, without exception.

November 17, 2022